| Cha. | Igama Lomkhiqizo | Isithombe somkhiqizo |

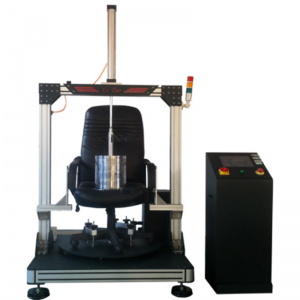

| I-LT-JJ29-A03 | Umshini Ophelele Wokuhlola Umatilasi (Ukugoqa kamatilasi, Ukucindezelwa komphetho, Ukuthamba Nokuqina, Umshini Wokuhlola Ukulinganisa Ubude) | |

| Ukucaciswa Kwezobuchwepheshe |

| 1. Indlela yokulawula:I-PLC + isikrini sokuthinta |

| 2. Idivayisi yokuhlola ukuqina kwe-Pavement:1) Umshini ongashayela i-roller ukuthi ihambe ngokuvundlile endaweni kamatilasi: umzuzu wokuzungezisa we-roller we-inertia ngu-(0.5±0.05) Kgm2, imvamisa yokulayisha kufanele ibe (16±2) izikhathi/min, kanye ne-static. umthwalo (1400± 7) N, inani lokuhlolwa> izikhathi ezingu-30,000; 2) I-roller: i-oval, ene-outer dimension tolerance of ± 2mm, indawo engaphezulu kufanele ibe lukhuni, ibushelelezi, ingabi nemihuzuko nokunye okungalungile kwendawo, ubude buyi-(1000±2)mm, i-coefficient yokungqubuzana iphakathi kuka-(0.2~0.5) , i-Roller Chamfer: R30, ubukhulu be-roller ububanzi: 300±1mm; 3) Motor: servo motor drive; 4) Ukuhlolwa kwe-stroke: 250mm ngakwesokunxele nangakwesokudla komugqa wesikhungo se-mattress; I-5) Ukunemba kwedivayisi yokulinganisa amandla akukho ngaphansi kwe-1%, ukunemba kwedivayisi ye-dimensional ayikho ngaphansi kuka-1mm, futhi ukuphambuka kwesikhundla sebhulokhi yokulayisha ngu-± 5mm. |

| 3. Idivayisi yokuhlola ukuqina kwe-Edge:I-1) Usayizi wephedi yokulayisha: 380 * 495 * 75mm, ubuso bayo buqinile futhi bushelelezi, buxhunywe emishini yokuhlola futhi ingajikeleza endizeni eqondile ezungeze i-axis evundlile; 2) Amandla okulayisha abheke phansi aqondile: 1000N; 3) Isamba senani lokuhlolwa: izikhathi ezingu-5000; 4) Isikhathi sokubamba: (3±1) s. |

| 4. Idivayisi yokulinganisa ubude:1) Ukunemba kwesilinganiso sobude: ± 0.5mm; 2) Iphedi yokulinganisa ubude: Indawo yokulinganisa iyisilinda esiyisicaba futhi esibushelelezi esiqinile; 3) Kala ububanzi bephedi: 100mm, chamfer R10; 4) Ijubane lesicelo sePad force: 100±20mm/min; 5) Amandla abheke phansi aqondile: Faka amandla angu-50N. Ngalesi sikhathi, ibanga eliphakathi kwendawo engezansi yendawo yokulinganisa yephedi eliyindilinga kanye nepuleti eliyisicaba ukuphakama kwendawo kamatilasi; Ubude bokulinganisa: Ubude bokuqala bendawo kamatilasi, ngemva kokuhlolwa ukuqina kwe-100 kanye ne-29,900, linganisa ukuphakama kwendawo ngokulandelanayo; Isistimu yokulinganisa ubude: Setha inani lamandla ngesofthiwe futhi usebenzise amandla aqonde phansi ngesivinini esingaguquki. |

| 5.Idivayisi yokuhlola ukuthambile nobulukhuni:1) Iphedi yokulayisha: isilinda esiqinile esinobuso obushelelezi nobubanzi obungu-355mm. Ubuso bokugcina buwubuso obuyindilinga obuyindilinga, irediyasi yokugoba kwendawo eyindilinga ingu-800mm, kanti irediyasi yokugoba yonqenqema lwangaphambili ingu-20mm; 2) Umthamo wokulayisha: 1000N; I-3) Isivinini sokugijima ngesikhathi sokulayisha nokuthulula: (90 ± 5) mm/min, uhlelo lungasethwa ngokungafanele phakathi kuka-0.01-200mm/min; 4) Ukulayisha ijika lokuchezuka: ubudlelwano phakathi kwevelu yamandla ekhishwa iphedi yokulayisha kusifanekiso kanye nevelu yokucindezeleka ehambisanayo; 5) Inani lokuqina (Hy) likamatilasi liyimithambeka emaphakathi yejika lokuchezuka kokulayisha ku-210N, 275N no-340N (isilinganiso samandla okulayisha N kanye nokujula kwephuzu lokulayisha mm); 6) Ibanga lokuqina: Iveza ukuthamba nobulukhuni bomkhiqizo ebangeni lezinombolo 1 kuya ku-10; Hs=1~5 umatilasi oqinile (inombolo encane, ilukhuni); Hs=6~10 umatilasi othambile (uma inani liphezulu, lithambile). |

| 6. Ukubukeka: Uhlaka oluyinhloko lwenziwe ngamaphrofayili e-aluminium yezimboni ezisezingeni eliphezulu enendawo ye-cross-sectional engu-80 * 80mm. Izingxenye zokuxhuma zidwetshwe ngeshidi lensimbi; |

| 7. Izinto zetafula lokuhlola: Isisekelo senziwe ngamaphrofayili e-aluminium yezimboni zezinga eliphezulu, futhi ipuleti lensimbi yetafula lipendwe ngokucwebezelayo; |

| 8. Ubude betafula lokuhlola ukusuka phansi: 180mm |

| 9. Ubukhulu bebonke: 3320*2400*2280mm (L*W*H) |

| 10. Isisindo: cishe amathani ayi-1.8 |

| 11. Ukunikezwa kwamandla namandla: AC2201V 50HZ isigaba esisodwa, cishe 2KW |

| 12. Ubuningi bebanga lesampula lokuhlolaUkuphakama: 2400 mm×2400mm×440mm |

| I-13.Isivinini sokuhlola: 90mm / min; 100mm/min |

| 14.Isikrini sohlelo singakhethwa ku-Simplified Chinese, Traditional Chinese, kanye nesiNgisi. |

| 15.Imodi yokubonisa ethambile nobulukhuni: izinombolo nombhalo. |

| 16. Amanani e-Force aboniswa kuyunithi ye-SI N |

| I-17.Ingakwazi ukulawula amandla kanye nesivinini sokuhamba futhi ibonise ukugudluka nokuphoqa amajika. (okungukuthi amajika athambile naqinile) |

| 18.Imibiko ingathunyelwa kumathebula e-Excel. |

| Amazinga Womhlangano |

| I-GB/T 26706-2011: Ifenisha efakwe upholstered. Umatilasi we-Palm fiber elastic |

| I-QB/T 1952.2-2023:Ifenisha ene-upholstered Umatilasi othambile wasentwasahlobo |

| Incazelo Yomkhiqizo |

| Ukuhlolwa kokuqina okugingqika komatilasi umshini oklanyelwe ukulingisa ukugingqika okungaguquki kwabantu phakathi nokulala. Ukuhlolwa kokuqina okugingqika kusebenzisa imojula yokulayisha eginqikayo ebekwe engxenyeni evundlile yokulayisha kamatilasi ukuze iginqike ngemvamisa ethile ukuze ihlole umatilasi. Ukulayisha okuphindiselayo kusetshenziselwa ukuhlola ikhono likamatilasi lokukwazi ukumelana nemithwalo yesikhathi eside ephindaphindayo. Ukuqina konqenqema lukamatilasi kuhlola ukuqina konqenqema lukamatilasi. Ukuhlolwa kokuthamba nokuqina kobuso ukuhlola ukuthamba nokuba lukhuni kukamatilasi ukuze kuhlangatshezwane nezidingo zazo zonke izinhlobo zemibhede. Umkhiqizi wamaphedi kanye nezidingo ezijwayelekile. Isetshenziselwa ukunquma ikhwalithi nempilo yesevisi yomatilasi futhi ithobela ngokuphelele izidingo zezindinganiso zikazwelonke zokuhlolwa kwemishini. Ifanele omatilasi abaqinile basentwasahlobo, omatilasi abajwayelekile basentwasahlobo, omatilasi begwebu, omatilasi abansundu be-fiber elastic, njll. |

| Izici |

| 1. Lo mshini uhlangabezana nezindlela zokuhlola ezi-4: ukuhlolwa kokuqina kokugingqika komgwaqo, ukuhlolwa kokuthambile nobulukhuni, ukuhlolwa kobude be-pad kanye nokuhlolwa kokucindezela onqenqemeni. |

| 2. Isebenzisa i-PLC + isilawuli sesikrini sokuthinta, ingakwazi ukubona imiphumela yokuhlola ezenzakalelayo ngokugcwele futhi ilawule izindlela ezimbili zokuhlola, ukusebenza okuzenzakalelayo ngokugcwele nemanuwali, ngenkinobho eyodwa. |

| 3. Ukukhethwa kwezinto kuyanelisa: indikimba eyinhloko yomshini ithatha isakhiwo sephrofayili yephrofayili ye-aluminium yamandla asezingeni eliphakeme, ama-rail guide rails, ama-servo motors, izinzwa zamandla, njll. |

| 4. I-servo motor isetshenziswa njengomshayeli ukuhlola ukuphakama kwephedi yokuhlola. Ukuhlolwa kwenziwa ngesivinini esishiwo yizinga futhi ijika elithambile nobulukhuni liyaboniswa. |

| 5. Irola: Yenziwe ngezinto zokhuni ezihlangabezana nezidingo ze-dynamic/static friction coefficient (0.2-0.5), kusetshenziswa ukucubungula okushumekiwe kwesitebhisi esingenalutho, esifakwe i-counterweight esingaphenduki ngerola, futhi kufanele ihlangabezane nezimfuneko zokuzungeza okujikelezayo. (0.5±0.05) kgm2, futhi yafinyelela imfuneko yamandla asebenzayo aqondile (1400±7)N. |

| 6. Ingxenye yokuhlola ukuqina kwe-pavement rolling yamukela ukwakheka komshini we-gantry, kusetshenziswa ama-thrust servo motors kanye neziqondiso zomugqa ezinembayo ezinomthwalo osindayo njengezingxenye zokudlulisela; isakhiwo sizinzile; ukusebenza kuzinzile futhi kuthembekile. |

| 7.Ukubekwa kwendawo emaphakathi yokuhlolwa okugoqayo, ngokuzenzakalelayo ukuthola indawo emaphakathi kamatilasi ngaphandle kokumiswa kabusha ngesandla, indawo yokuqala ye-PLC. |

| 8. I-motor-driven mechanism isetshenziselwa ukusunduza i-roller ukuze ihambe ngokuvundlile nangokuqondile. I-roller intanta phezulu naphansi ngokukhululekile nomatilasi, futhi ilayishwa ngomjikelezo endaweni eshiwo (iphutha lamandla asetshenzisiwe ngu-±10%). Imvamisa yokulayisha yizikhathi (16±2). /min. |

| 9. Ukuze kube lula ukufakwa nokulungisa iphutha komshini nezifanekiso, umshini wamukela ukuhlanganiswa okungakhipheka, futhi isisekelo samukela uhlaka lwephrofayela ye-aluminium. Ubude bayo akufanele budlule ku-180mm, okwenza kube lula ukuhamba nokuthutha, futhi kulula ukuyisebenzisa. |

| 10. Ukuvikelwa kwedatha: idatha yokuhlola igcinwa ngokuzenzakalelayo lapho ugesi ucishiwe (idatha ingagcinwa ngokuzenzakalelayo kusixhumi esibonakalayo ngemva kokuba amandla ecishiwe). |

| 11. Imishini nezinqubo kufanele zibe nemisebenzi yokuvikela ekabili ukuze kuvinjelwe ngempumelelo ukwehluleka kwesistimu yokuphakamisa kanye ne-actuator ngenxa yokungasebenzi kahle nokuqinisekisa ukuphepha kwemishini. Umsebenzi we-alamu yesistimu, i-alamu ezenzakalelayo nehlakaniphile ngemva kwezimo ezingavamile nokuqedwa kokuhlolwa. |