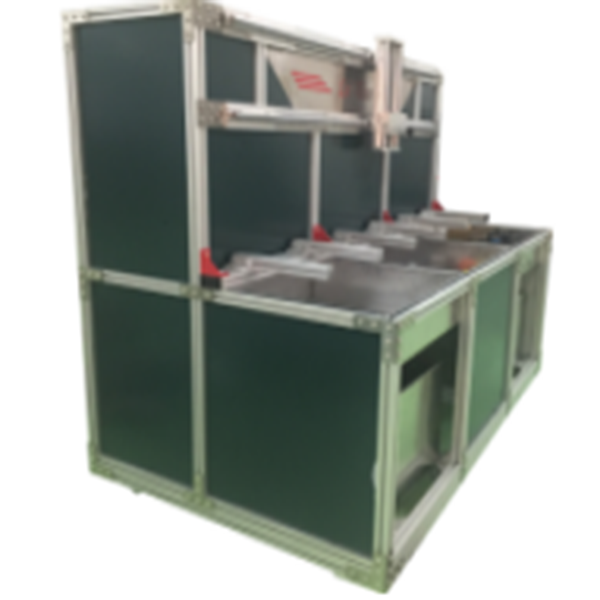

LT -WY01 Intelligent amanzi nozzle olunzulu umshini wokuhlola ukusebenza

Imingcele Yezobuchwepheshe

| Inombolo yomkhiqizo | Ngokusho kwegama lephrojekthi | Ufuna ukubuza |

| 1 | I-voltage esebenzayo | I-AC380V yezigaba ezintathu |

| 2 | Indawo yokuhlola | Amanzi: 5-20℃, 38℃, 60℃ (3 amathangi amanzi) |

| 3 | Isiteshi sokuhlola | Iziteshi ezi-3, isiteshi 1: ukugeleza kwe-nozzle kanye nokuzwela (futhi ingahlangabezana nokuhlolwa okungenani kwezinhlobo ezintathu zesakhiwo se-nozzle: evulekile esibambo, ivule eceleni futhi ivule ngamadigri angu-45). Isiteshi sesi-2: izinga lokusebenzisa amanzi kahle lombhobho neshawa, izinga lokugeleza kweshawa, isiteshi 3: ibanga lokulawula, ukuguqulwa kwamandla kagesi, isikhathi sokuvula nokuvala, idivayisi yokuthinta, ukusetshenziswa kwamandla omshini wonke, ukulwa nokuphazamiseka (iziteshi ezintathu ngesikhathi esisodwa ukufaka imikhiqizo), ukuvikelwa kokwehluleka kwamandla, ngaphansi kokuvikelwa kwamandla kagesi, ukulawulwa kwamanzi okuphelelwe yisikhathi, ukuhlolwa kwesando samanzi. |

| 4 | Hlola ububanzi bomkhiqizo | Umbhobho, ishawa, ipayipi, okokufaka amanzi, i-Engeli ye-valve yesokudla |

| 5 | Izinto zamathuluzi | Insimbi engagqwali + ithusi +POM |

| 6 | Izikhathi zokusetha zokuhlola | 1 ~ 999999 izikhathi ezihleliwe |

| 7 | shayela | I-Servo motor + cylinder |

| 8 | Ukubala ukunemba | Ibanga: 0.1 isekhondi ~ 999.99 amaminithi, ukunemba kwesikhathi: 0.1 isekhondi |

| 9 | Inzwa yokucindezela | 0-2 mpa, 0.5 esikalini sika-Richter akunakwenzeka |

| 10 | Imitha yokugeleza | Ibanga lokulinganisa 1-30l /M, ukunemba kokulinganisa 0.1l /M |

| 11 | Iphampu lamanzi | Ingcindezi emile ye-0.05-1.6MPa iyatholakala |

| 12 | Ukuzinza kwe-hydraulic | ± 0.01mpa (ngezansi kuka-0.5mpa), ± 0.05mpa (ngaphezulu kuka-0.5mpa) |

| 13 | Ithuluzi lokubonisa idijithali ye-Hydraulic | Bonisa ukunemba okungu-0.001mpa |

| 14 | Ithuluzi lokubonisa izinga lokushisa lamanzi ledijithali | Bonisa ukunemba 0.1℃ |

| 15 | Ithuluzi lokubonisa ledijithali eligelezayo | Bonisa ukunemba okungu-0.1l/M |

| Ukuthobela izindinganiso nezigatshana | ||

| Isigaba somkhiqizo | Kusho uStandard | Izindinganiso ze-athikili |

| Ceramic seal nozzle | I-GB 18145-2014 | 8.6.3.1 ukugeleza |

| Ceramic seal nozzle | I-GB 18145-2014 | 8.6.3.2 ukuzwela (kusebenza kusibambo esisodwa kanye nombhobho wokulawula kabili) |

| Ceramic seal nozzle | I-GB 18145-2014 | 8.8.1.1 ukugeleza kombhobho wokuzivala wokubambezeleka kwesikhathi |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.4.1 lawula iphutha lebanga |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.4.2 umthelela wokushintsha kwamandla kagesi |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.5 isikhathi sokuvula nesokuvala |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.6 ukusetshenziswa kwamandla sekukonke |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.7 ukusebenza okungahambisani nokuphazamiseka |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.8 ukwehluleka kwamandla kanye nokuvikelwa kwe-voltage engaphansi |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.10.1 ukugeleza kombhobho neshawa |

| Umbhobho ongaxhunywanga | CJ/T 194-2014 | 8.13 ukusebenza kwesando samanzi |

| Umshini wokuphakela amanzi ongenayo inductive | JC/T2115-2012 | 7.4 ukuhlola ibanga lokulawula |

| Umshini wokuphakela amanzi ongenayo inductive | JC/T2115-2012 | 7.5 Ukuhlolwa kokusebenza okungahambisani nokuphazamiseka |

| Umshini wokuphakela amanzi ongenayo inductive | JC/T2115-2012 | 7.6 ukuhlolwa kokuvikela okuzenzakalelayo |

| Umshini wokuphakela amanzi ongenayo inductive | JC/T2115-2012 | 7.7.1 Ukuhlolwa kokusebenza kokugeleza kombhobho neshawa |

| Umshini wokuphakela amanzi ongenayo inductive | JC/T2115-2012 | 7.11 ukuhlolwa kwesando samanzi |

| Umlomo wamanzi | I-GB25501-2010. | 5 indlela yokuhlola |

| ishawa | I-GB 28378-2012 | 5.1 ukuhlolwa kokufana kokugeleza |

| ishawa | I-GB 28378-2012 | 5.2 ukuhlolwa kokugeleza |

| Impompi yezinga lokushisa engashintshi | QB 2806-2006 | 6.4.3 ukugeleza |

| Ukulibaziseka kwesikhathi umlomo wombhobho wokuzivala | I-QB/T 1334-2013 | 8.8.1.2 izinga lokugeleza lombhobho wokungeniswa |

| Ukulibaziseka kwesikhathi umlomo wombhobho wokuzivala | I-QB/T 1334-2013 | 8.8.1.3 okunye ukugeleza kombhobho |

| Ukulibaziseka kwesikhathi umlomo wombhobho wokuzivala | I-QB/T 1334-2013 | 8.8.2 ukuzwela (kwesibambo esisodwa kanye ne-double control nozzle) |