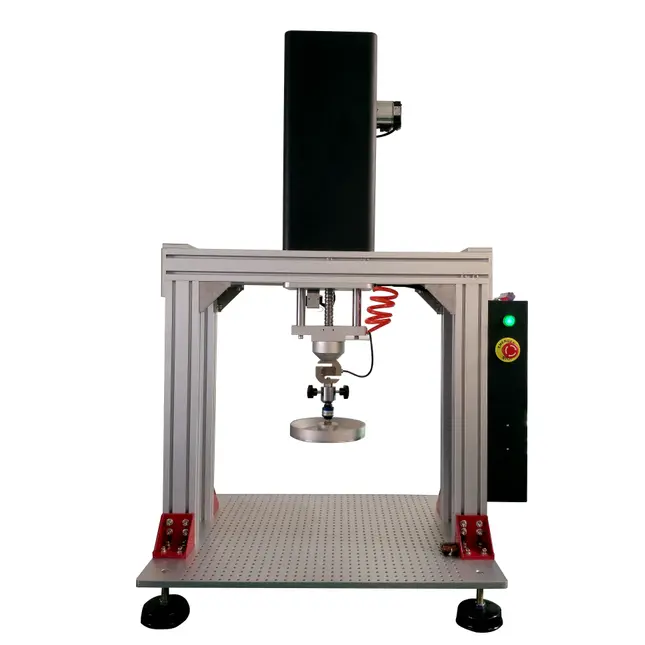

The sponge indentation hardness tester has become the key equipment for measuring the hardness of foam, soft materials, rubber and other materials. Its main function is to apply indentation to the sample under a certain load, measure the hardness value, and evaluate the mechanical properties of the material. In order to ensure the accuracy and reliability of the test results, the stability, software updates, and ease of operation of the Sponge indentation hardness testing machine have become important considerations in its design and use.

The Sponge indentation hardness testing machine achieves hardness testing through precise control of load and depth, and any unstable mechanical structure may lead to testing errors. For example, factors such as vibration and temperature fluctuations that may occur during the testing process can affect the accuracy of the test results. Therefore, the design of the equipment needs to ensure a high-strength structure and excellent anti-interference ability to reduce the impact of external factors on testing accuracy. In addition, the mechanical performance of the testing machine should be as accurate as possible. By using precise pressure sensors and high-precision control systems, accurate mechanical data can be provided for each indentation to avoid errors.

The performance of Sponge indentation hardness testing machine is closely related to the software. With the continuous advancement of technology, the compatibility between hardware and software has become particularly important. The control system and data analysis software of the equipment need to be updated in a timely manner to adapt to the ever-changing measurement standards and user needs. For example, with the changes in hardness testing standards and the emergence of new materials, software needs to be adjusted and optimized according to different testing conditions. Modern testing machines are typically equipped with powerful data processing software that can provide multiple measurement modes and custom settings, helping users obtain more comprehensive and accurate results. Therefore, keeping the device software updated in a timely manner can not only improve testing efficiency, but also ensure that the device continues to stay ahead in the constantly changing market environment.

Modern Sponge indentation hardness testing machines are typically designed with user-friendly interfaces that allow users to quickly get started and reduce errors caused by operational complexity. The touch screen and intuitive graphical interface make the testing process simpler, while the automated testing process greatly reduces the difficulty of manual operation. In addition, the equipment is usually equipped with an intelligent calibration system that automatically detects and calibrates the accuracy of the hardness tester, ensuring the consistency of each test result. For enterprises, operational convenience not only improves work efficiency, but also reduces the risk of errors and equipment damage caused by improper operation.

Post time: Nov-05-2024