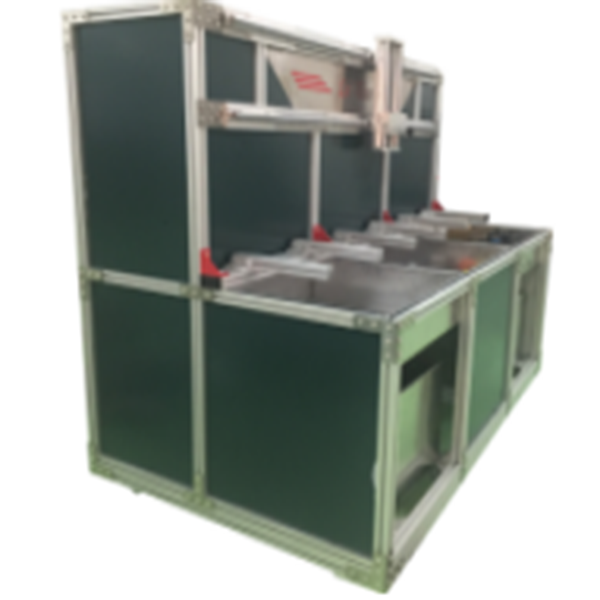

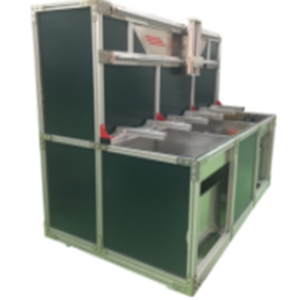

LT -WY01 Intelligent water nozzle comprehensive performance testing machine

Technical Parameters

| The serial number | According to project name | Want to ask |

| 1 | Working voltage | Three-phase AC380V |

| 2 | The test medium | Water: 5-20℃, 38℃, 60℃ (3 water tanks) |

| 3 | Test station | 3 stations, station 1: nozzle flow and sensitivity (and can meet the test of at least three types of nozzle structure: open on handle, open on side and open at 45 degrees). Station 2: water consumption efficiency level of nozzle and shower, shower flow rate, station 3: control distance, voltage change, opening and closing time, touch device, energy consumption of the whole machine, anti-interference (three stations at the same time to install products), power failure protection, under voltage protection, timeout water control, water hammer test. |

| 4 | Test product range | Nozzle, shower, hose, drainage fittings, right Angle valve |

| 5 | Tooling material | Stainless steel + copper +POM |

| 6 | Test setting times | 1 ~ 999999 times settable |

| 7 | drive | Servo motor + cylinder |

| 8 | Counting accuracy | Range: 0.1 second ~ 999.99 minutes, timing accuracy: 0.1 second |

| 9 | Pressure sensor | 0-2 mpa, 0.5 on the Richter scale are unlikely |

| 10 | Flow meter | Measuring range 1-30l /M, measuring accuracy 0.1l /M |

| 11 | The water pump | Static pressure of 0.05-1.6MPa is available |

| 12 | Hydraulic stability | ± 0.01mpa (below 0.5mpa), ± 0.05mpa (above 0.5mpa) |

| 13 | Hydraulic digital display instrument | Display accuracy 0.001mpa |

| 14 | Water temperature digital display instrument | Display accuracy 0.1℃ |

| 15 | Flow digital display instrument | Display accuracy 0.1l /M |

| Comply with standards and clauses | ||

|

Product class |

Standard said |

Article standards |

|

Ceramic seal nozzle |

GB 18145-2014 |

8.6.3.1 flow |

|

Ceramic seal nozzle |

GB 18145-2014 |

8.6.3.2 sensitivity (applicable to single handle and double control nozzle) |

|

Ceramic seal nozzle |

GB 18145-2014 |

8.8.1.1 flow of time-delay self-closing nozzle |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.4.1 control distance error |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.4.2 influence of voltage changes |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.5 opening and closing time |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.6 overall energy consumption |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.7 anti-interference performance |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.8 power failure and under-voltage protection |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.10.1 flow of nozzle and shower |

|

Non-contact nozzle |

CJ/T 194-2014 |

8.13 water hammer performance |

|

Non-contact inductive water supply appliance |

JC/T2115-2012 |

7.4 control distance test |

|

Non-contact inductive water supply appliance |

JC/T2115-2012 |

7.5 anti-interference performance test |

|

Non-contact inductive water supply appliance |

JC/T2115-2012 |

7.6 automatic protection test |

|

Non-contact inductive water supply appliance |

JC/T2115-2012 |

7.7.1 flow performance test of nozzle and shower |

|

Non-contact inductive water supply appliance |

JC/T2115-2012 |

7.11 water hammer test |

|

Water mouth |

GB25501-2010. |

5 test method |

|

shower |

GB 28378-2012 |

5.1 flow uniformity test |

|

shower |

GB 28378-2012 |

5.2 flow test |

|

Constant temperature faucet |

QB 2806-2006 |

6.4.3 flow |

|

Time-delay self-closing nozzle |

QB/T 1334-2013 |

8.8.1.2 induction nozzle flow rate |

|

Time-delay self-closing nozzle |

QB/T 1334-2013 |

8.8.1.3 other nozzle flows |

|

Time-delay self-closing nozzle |

QB/T 1334-2013 |

8.8.2 sensitivity (for single handle and double control nozzle) |