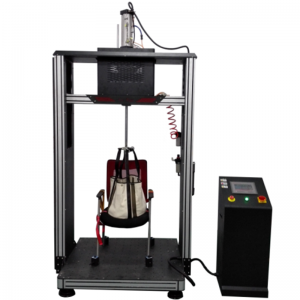

LT-JJ10-A06 Six Channel Outdoor Table and Chair Comprehensive Mechanical Testing Machine

Compliant with standards

EN 581-2:2015 Outdoor furniture – Camping, household and contract seats and tables – Part 2: Mechanical safety requirements and test methods for seats

EN 581-3:2007 Outdoor furniture – Camping, household and contract seats and tables – Part 3: Mechanical safety requirements and test methods for tables – Tables should be tested in the order listed in Table 1.

technical parameter

3.1. Sensors: 200kg, 500kg, configure corresponding sensors according to testing requirements.

3.2. Machine board size:

Length: 2600mm (including computer length 5240mm) * Width: 1980mm (including cylinder extension 4530mm) * Height: 2316mm

Instrument projection size:

Length: 4173mm (including computer length of 4800mm) * Width: 3616mm (including cylinder extension of 4530mm) * Height: 2316mm

3.3. Load element accuracy: 1/1000

3.4. Test accuracy: Static: ± 1% Dynamic force: ± 3%

3.5. Testing device:

Cylinder testing device: There are six sets in total, each cylinder is equipped with a separate set of electrical proportional valves to accurately control the air pressure output.

Note: Cylinder brand: Taiwan Yadeke; Electric proportional valve brand: Japanese SMC imported brand;

3.6. Displacement stroke: 0-500mm

3.7. Time for various actions: 0.01-30s can be set arbitrarily.

3.8. Test speed: 1-30 times/minute can be set arbitrarily.

3.9. Test times: can be set arbitrarily between 0-999999 times.

3.10. Power off memory: It has the functions of stop/power off memory and breakpoint detection shutdown. If the machine stops or loses power midway, the test will be automatically saved

Test results.

3.11. Shutdown method: Stop the machine and sound an alarm when the number of tests is reached.

3.12. Sensor: Well known brand sensor.

3.13. The equipment has a fault self diagnosis system, which facilitates inspection and troubleshooting.

3.14. The basic framework adopts a gantry reinforcement design and a modular structure of high-strength aluminum metal frame. The bottom frame adopts a three-dimensional structure, which is stable in structure.

3.15. Base: High strength industrial aluminum profile+national standard 45 steel, thickness ≥ 10mm, strong magnet fixed sample

3.16. The program interface can select language versions such as Simplified Chinese, Traditional Chinese, English, etc., and can be freely changed on the program settings page.

3.17. Power supply: 220V, power: 3KW

3.18. Gas source: The gas source has been filtered and dried, with a pressure of ≥ 0.5MPa; Flow rate: ≥ 800L/min;

3.19. The instrument adopts a computer+force sensor+encoder to form a closed-loop control of force and displacement. Computer integrated control system, with multi-channel data acquisition, can simultaneously control multiple channels and multiple test axes. It can also independently set the action of a certain cylinder or motor, including single or multiple reciprocating tests. It can also set two pairs of coordinated actions and reciprocating tests in the same direction but different directions. Each channel needs to be operated through a reference synchronization time to ensure the synchronization of actions and data processing. Different channels can be grouped for control. If the sample of one channel is damaged, the associated channel in the same group will stop at the same time, and the remaining channels can continue to work. The operation interface is simple, the functions are complete, the high-speed response is used, the operation is very easy, the actions are precise, and the failure rate is low.

3.20. It can achieve control of force and displacement speed, display displacement time, force time, force displacement, force displacement maximum and minimum life curves (the change curves of the maximum force value and maximum displacement value of each channel in each cycle), etc.

No need for manual adjustment of force and displacement, displaying the displacement offset for each time, achieving intelligent integrated control.