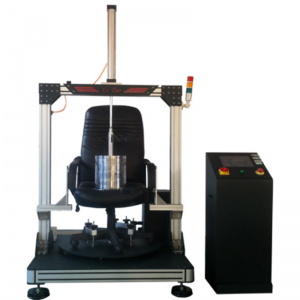

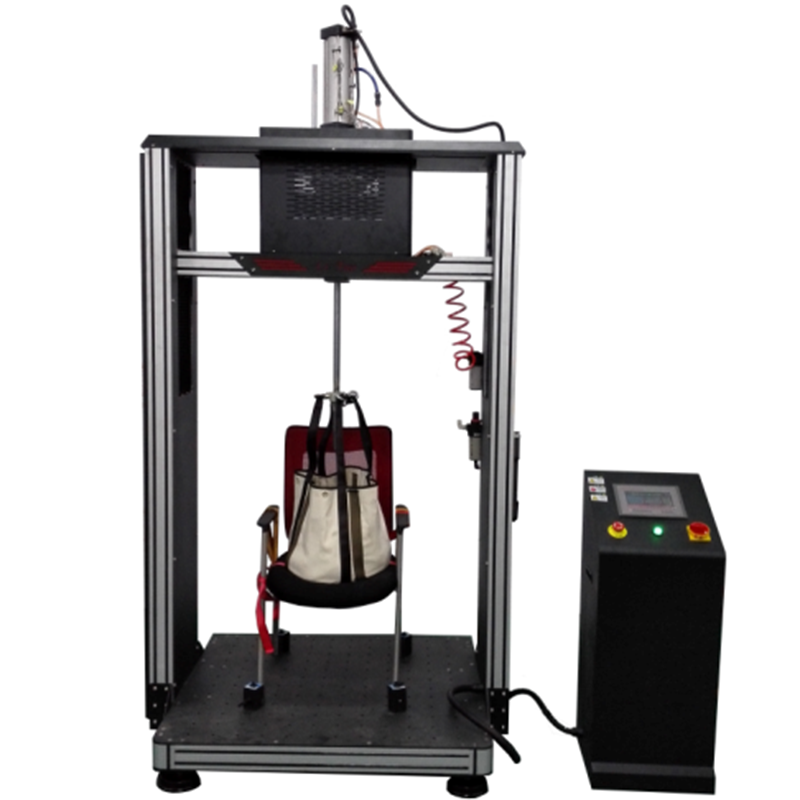

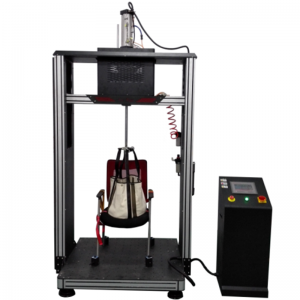

LT-JJ03 Office chair seat surface impact testing machine

Technical parameters

|

1. Maximum impact height |

250mm |

|

2. Impact frequency |

5-15 times/min |

|

3. Sample limit |

L 1000×W 1000× seat H (300 ~ 650mm) |

|

4. Impact weight |

125~ 500Ibs(pressure ≥ 0.6mpa)

|

|

5. Power supply (power) |

220VAC/5A, 50Hz |

|

6. Air source |

Air pressure: ≥ 0.6mpa; Flow rate: ≥800L/min |

|

7. Body size |

about 1350* 1000* 2200mm (L* W * Ht) |

|

8. Weight |

about 450kg |

|

9. Control system

|

①Separate industrial control box, with break point check out stop function; ②The touch screen displays the impact times and speed in real time, with stop/power failure memory function; ③Electric height adjusting drive system; ④Action control mechanism: low electromagnet electric absorption,cylinder driven up, high power loss release; ⑤Hydraulic buffer to reduce noise. |

|

Product features |

|

|

1. Two functions can be realized: repeated impact on the seat surface and one-time impact on the seat surface; |

|

|

2. Aluminum profile frame structure, stainless steel test platform, beautiful structure; |

|

|

3. Use electromagnet to absorb and release, completely simulate the state of free fall, with no resistance and low noise during the fall; |

|

|

4. Use the "foot cup" structure in the horizontal direction of the chair to keep the position, so that the chair is not constrained by external forces in the vertical direction; |

|

|

5. Easy to operate without any special tools; Memory function of power failure; |

|

|

6. Different control forms are optional. |

|

|

Conform to the standard |

|

|

QB/T 2280-2016 |

BIFMA X5.1-2017 |

|

BIFMA X5.1-2017 |

|

-300x225.jpg)