| Tsis muaj. | Khoom npe | Khoom duab |

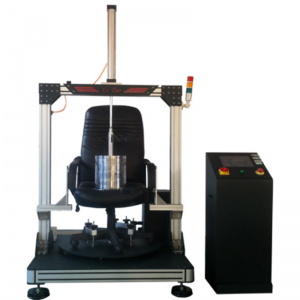

| LT-JJ 29-A03 | Cov ntaub ntawv pov thawj kev sim tshuab (Pom txaj Rolling, Ntug nias, Softness thiab Hardness, Qhov Siab Ntsuas Ntsuas Tshuab) | |

| Technical Specification |

| 1. Tswj txoj kev:PLC + kov npo |

| 2. Pavement durability test device:1) Cov cuab yeej siv tshuab uas tuaj yeem tsav cov menyuam txav mus rau qhov kab rov tav ntawm lub txaj: lub sijhawm sib hloov ntawm cov menyuam ntawm inertia yog (0.5 ± 0.05) Kgm2, lub sijhawm thauj khoom yuav tsum yog (16 ± 2) zaug / min, thiab qhov zoo li qub load yog (1400 ± 7) N, tus lej xeem> 30,000 zaug; 2) Cov menyuam: oval, nrog rau sab nraud qhov ntev ntawm ± 2 hli, qhov saum npoo yuav tsum tawv, du, tsis muaj khawb thiab lwm yam tsis xws luag, qhov ntev yog (1000 ± 2) hli, qhov sib txhuam coefficient ntawm (0.2 ~ 0.5) , cov menyuam Chamfer: R30, siab tshaj plaws rau cov menyuam txoj kab uas hla: 300 ± 1mm; 3) Lub cev muaj zog: servo lub cev muaj zog tsav; 4) Kev kuaj mob stroke: 250mm ntawm sab laug thiab sab xis ntawm lub txaj chaw kab; 5) Qhov tseeb ntawm lub zog ntsuas ntsuas tsis tsawg dua 1%, qhov tseeb ntawm qhov ntsuas qhov ntsuas tsis tsawg dua 1 hli, thiab qhov sib txawv ntawm qhov chaw thau khoom yog ± 5 hli. |

| 3. Ntug durability xeem ntaus ntawv:1) Loading pad loj: 380 * 495 * 75mm, nws nto yog tawv thiab du, nws txuas nrog cov khoom siv kuaj thiab tuaj yeem tig rau ntawm lub dav hlau ntsug ncig ntawm kab rov tav; 2) Vertical downward loading quab yuam: 1000N; 3) Tag nrho cov kev xeem: 5000 zaug; 4) Lub sijhawm tuav: (3 ± 1) s. |

| 4. Kev ntsuas qhov siab:1) Kev ntsuas qhov siab: ± 0.5mm; 2) Qhov ntsuas qhov siab: Qhov ntsuas qhov saum npoo yog lub tog raj kheej thiab du nruj; 3) Ntsuas txoj kab uas hla ntawm lub ncoo: 100mm, chamfer R10; 4) Pad quab yuam daim ntawv thov ceev: 100 ± 20mm / min; 5) Vertical downward force: Siv 50N quab yuam. Lub sijhawm no, qhov kev ncua deb ntawm qhov qis ntawm qhov ntsuas qhov chaw ntawm lub voj voog thiab lub phaj tiaj tus yog qhov siab ntawm lub txaj txaj; Kev ntsuas qhov siab: Thawj qhov siab qhov siab ntawm lub txaj, tom qab 100 thiab 29,900 qhov kev ntsuam xyuas durability, ntsuas qhov siab ntawm qhov chaw raws li; Kev ntsuas qhov siab: Teem tus nqi quab yuam los ntawm software thiab siv lub zog vertically downward ntawm qhov ceev tsis tu ncua. |

| 5.Softness thiab hardness kuaj ntaus ntawv:1) Chaw thau khoom ncoo: lub tog raj kheej nruj nrog lub ntsej muag du thiab txoj kab uas hla ntawm 355mm. Lub ntsej muag kawg yog convex spherical nto, lub vojvoog ntawm curvature ntawm tus kheej kheej yog 800mm, thiab lub vojvoog ntawm curvature ntawm nws pem hauv ntej ntug yog 20mm; 2) Chaw thau khoom muaj peev xwm: 1000N; 3) Kev khiav ceev thaum thauj khoom thiab tshem tawm: (90 ± 5) mm / min, lub kaw lus tuaj yeem teeb tsa arbitrarily ntawm 0.01-200mm / min; 4) Loading deflection nkhaus: kev sib raug zoo ntawm tus nqi quab yuam exerted los ntawm lub loading ncoo ntawm tus qauv thiab tus nqi sib cuam tshuam; 5) Tus nqi hardness (Hy) ntawm lub txaj yog qhov nruab nrab txoj kab nqes ntawm qhov chaw thau khoom deflection nkhaus ntawm 210N, 275N thiab 340N (qhov sib piv ntawm kev thauj khoom quab yuam N thiab qhov chaw thau khoom kev nyuaj siab qhov tob mm); 6) Qib Hardness: Nws qhia qhov softness thiab hardness ntawm cov khoom nyob rau hauv ntau yam ntawm cov zauv 1 txog 10; Hs = 1 ~ 5 yog lub txaj tawv (tus lej me dua, qhov nyuaj dua); Hs = 6 ~ 10 yog ib lub txaj mos (tus lej siab dua, softer). |

| 6. Cov tsos: Lub ntsiab ncej yog ua los ntawm cov qib high-qib muaj txhuas profiles nrog ib tug ntoo khaub lig-sectional cheeb tsam ntawm 80 * 80mm. Cov khoom sib txuas yog pleev xim nrog cov ntawv hlau; |

| 7. Cov ntaub ntawv kuaj: Lub hauv paus yog ua los ntawm qib high-qib industrial aluminium profiles, thiab lub rooj steel phaj yog glossy pleev xim rau; |

| 8. Test rooj qhov siab ntawm hauv av: 180mm |

| 9. Zuag qhia tag nrho qhov ntev: 3320 * 2400 * 2280mm (L*W*H) |

| 10. Nyhav: txog 1.8 tons |

| 11. Fais fab mov thiab lub zog: AC2201V 50HZ ib theem, txog 2KW |

| 12. Cov qauv xeem ntau tshaj plawsNtev: 2400mm×2400 hli×4 40mm |

| 13.Test Ceev: 90mm / min; 100mm / min |

| 14.Qhov kev tshuaj ntsuam xyuas tuaj yeem xaiv los ntawm Suav yooj yim, suav suav, thiab lus Askiv. |

| 15.Soft thiab hardness zaub hom: cov lej thiab ntawv. |

| 16.Force qhov tseem ceeb tau qhia hauv SI unit N |

| 17.Nws tuaj yeem tswj tau qhov quab yuam thiab txav ceev thiab tso saib qhov txav thiab quab yuam nkhaus. (xws li mos thiab tawv nkhaus) |

| 18.Cov ntaub ntawv tuaj yeem raug xa tawm mus rau Excel rooj. |

| Kev Sib Tham Cov Qauv |

| GB/T 26706-2011: Upholstered rooj tog. Palm fiber ntau elastic txaj |

| QB/T 1952.2-2023:Upholstered rooj tog Caij nplooj ntoos hlav mos txaj |

| Product Description |

| Lub txaj dov durability test yog lub tshuab tsim los simulate qhov dov tsis tu ncua ntawm tib neeg thaum pw tsaug zog. Lub dov durability xeem siv ib tug dov loading module muab tso rau hauv kab rov tav loading ib feem ntawm lub txaj kom yob ntawm ib tug tej zaus los ntsuam xyuas lub txaj. Reciprocating loading yog siv los ntsuam xyuas lub txaj lub peev xwm los tiv thaiv lub sij hawm ntev repetitive dov loads. Lub txaj ntug durability feem ntau kuaj lub txaj ntug durability. Qhov kev ntsuam xyuas qhov muag thiab qhov tawv tawv yog los ntsuas qhov muag thiab qhov tawv ntawm lub txaj kom tau raws li qhov xav tau ntawm txhua hom txaj. Pad chaw tsim tshuaj paus thiab tus qauv yuav tsum tau. Nws yog siv los txiav txim siab qhov zoo thiab kev pabcuam lub neej ntawm lub txaj thiab nruj me ntsis raws li cov kev cai ntawm lub teb chaws cov qauv rau kev kuaj tshuab. Haum rau lub caij nplooj ntoos hlav muaj zog txaj, lub caij nplooj ntoos hlav zoo tib yam txaj txaj, ua npuas ncauj txaj, xim av fiber ntau elastic txaj, thiab lwm yam. |

| Nta |

| 1. Cov cuab yeej no ua tau raws li 4 txoj kev sim: pavement rolling durability test, softness and hardness test, pad surface height test and edge pressing test. |

| 2. Siv PLC + kov lub vijtsam tswj, nws tuaj yeem paub qhov kev sim siab tsis siv neeg thiab tswj ob hom kev sim, ua haujlwm tsis siv neeg thiab phau ntawv, nrog ib lub pob. |

| 3. Kev xaiv cov khoom txaus siab: lub cev tseem ceeb ntawm lub tshuab txais cov qauv kev lag luam muaj zog aluminium profile ncej, linear qhia rails, servo motors, quab yuam sensors, thiab lwm yam. |

| 4. Lub servo lub cev muaj zog yog siv los ua tus tsav tsheb los ntsuas qhov siab ntawm qhov ntsuas ntsuas. Qhov kev ntsuam xyuas yog nqa tawm ntawm qhov ceev uas tau teev tseg los ntawm tus qauv thiab qhov muag muag thiab hardness nkhaus yog tso tawm kom pom. |

| 5. Cov menyuam: ua los ntawm cov khoom siv ntoo uas ua tau raws li qhov yuav tsum tau muaj ntawm dynamic / zoo li qub kev sib txhuam coefficient (0.2-0.5), siv hollow ladder embedded processing, nruab nrog lub counterweight uas tsis tig nrog cov menyuam, thiab yuav tsum ua kom tau raws li qhov yuav tsum tau muaj ntawm rotational inertia. (0.5 ± 0.05) kgm2, thiab mus txog qhov yuav tsum tau ntawm ntsug thov quab yuam (1400 ± 7) N. |

| 6. Cov pavement dov durability xeem ib feem tau txais ib lub gantry mechanical qauv, siv cov thrust servo motors loj thiab high-precision hnyav-load linear qhia raws li kis tau tus mob qhov chaw; tus qauv ruaj khov; kev ua haujlwm ruaj khov thiab txhim khu kev qha. |

| 7.Positioning ntawm qhov nruab nrab ntawm qhov ntsuas dov, tuaj yeem nrhiav qhov nruab nrab ntawm lub txaj tsis muaj phau ntawv repositioning, PLC pib qhov chaw. |

| 8. Lub cev muaj zog-tsav mechanism yog siv los thawb cov menyuam txav mus rau kab rov tav thiab linearly. Cov menyuam ntab nce thiab nqis dawb nrog lub txaj pw, thiab thauj khoom cyclically hauv thaj chaw uas tau teev tseg (qhov yuam kev yuam kev yog ± 10%). Lub sijhawm thauj khoom yog (16 ± 2) zaug. / min. |

| 9. Txhawm rau kom yooj yim rau kev teeb tsa thiab kev debugging ntawm lub tshuab thiab cov qauv, lub tshuab txais kev sib dhos detachable, thiab lub hauv paus adopts aluminium profile ncej. Nws qhov siab yuav tsum tsis pub tshaj 180mm, ua kom yooj yim txav thiab thauj, thiab ntau tus neeg siv-phooj ywg. |

| 10. Kev tiv thaiv cov ntaub ntawv: cov ntaub ntawv xeem tau txais kev cawmdim thaum lub hwj chim tawm (cov ntaub ntawv tuaj yeem khaws cia rau hauv lub interface tom qab lub hwj chim tawm). |

| 11. Cov tshuab thiab cov txheej txheem yuav tsum muaj kev tiv thaiv dual lub luag haujlwm txhawm rau tiv thaiv qhov tsis ua haujlwm ntawm lub tshuab nqa thiab lub tshuab hluav taws xob vim kev ua haujlwm tsis raug thiab xyuas kom muaj kev nyab xeeb ntawm cov khoom siv. System tswb muaj nuj nqi, tsis siv neeg thiab ntse tswb tom qab txawv txav tej yam kev mob thiab xeem tiav. |