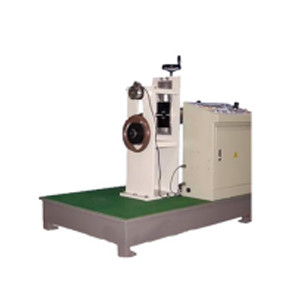

LT-CZ 14 Tyre puncture lub zog kuaj tshuab | puncture zog kuaj tshuab

| Technical parameters |

| 1. Qhov siab tshaj plaws load caij LOAD: 2000 KG, 5000 KG yeem |

| 2. Kev daws teeb meem: 1 / 50,000,0 |

| 3. Unit switching: txhua yam thoob ntiaj teb feem ntau siv units tuaj yeem hloov tau arbitrarily |

| 4. Precision ntau yam ntawm rub siab: ± 3 / 1000 |

| 5. Kev ntsuas ceev: lub computer tswj tsis yog ntu kom muaj nuj nqis, 0.001 ~ 500mm / min |

| 6. Displacement decomposition degree: 0.001mm |

| 7. tuaj yeem ua rau kev ntxhov siab thiab lub zog, thiab tso saib nkhaus, tuav lub siab thiab nro |

| 8. Qhov chaw zoo ntawm cov phaj siab qis: 600 * 1000mm, qhov chaw zoo ntawm sab saud thiab qis phaj siab: 1000mm, ib puag ncig tiv thaiv npog |

| 9. Cov cuab yeej tiv thaiv: suav nrog kev tswj kev nce thiab nqis mus ncig, qhov kev pab cuam teeb tsa qhov siab tshaj plaws, qhov siab tshaj plaws txuas ntxiv, tsis siv neeg kaw thaum muaj xwm txheej ceev, lub cev muaj zog tsav yog servo lub cev muaj zog, tag nrho tswj los ntawm lub computer ceev thiab mus ncig, txawv ntawm cov tsoos. AC, DC lub cev muaj zog tswj los ntawm qhov hluav taws xob, yuav tsum tau tswj hauv cov kab lus sib txawv. |

| 10. Ntxiv ib daim npog tiv thaiv. |

| 11. Nyhav: 265 kg |

| 12. Fais fab mov: 1,220V, 15A |

| 13. Nta: nrog rau lub computer xim tshuaj ntsuam luam ntawv tshuab; lub tshuab luam ntawv tuaj yeem luam tawm lub khoos phis tawj tso saib lub siab nkhaus, tsis tas yuav ntxiv X. Y recorder, qhov kev pab cuam tuaj yeem ua haujlwm raws li WINDOWS kom swb tus nas tswj, tswj qhov screen hom, Suav thiab lus Askiv zaub yog yooj yim rau kev khiav lag luam. |

| 14. Accessories: ib txheej ntawm puncture clamp |

| 15. Lub cev muaj zog: Panasonic servo lub cev muaj zog, Nyiv. |

| 16. Software system: universal rub siab thiab high-precision system |

| 17. Khoos phis tawj: Lenovo muaj cov khoos phis tawj |

| 18. Lub tshuab luam ntawv: ib lub tshuab luam ntawv Canon, Nyiv |

| 19. Lub cav loj xim: tshuab kem dawb, tshuab lub rooj: dub |

| 20. Screw pas nrig: lub pob ntsia hlau pas nrig |

| Khoom nta |

| 1. Kev tsim sab nrauv zoo heev. Nyob rau hauv peb lub tuam txhab tau ntau xyoo, tus qauv tau zoo heev rau cov tsos ntawm cov khoom, tsim ntau yam khoom piv rau txawv teb chaws qauv, nto yog electrostatic txhaj; |

| 2. Cov khoom tseem ceeb thiab cov khoom siv. Siv cov npe nrov thoob ntiaj teb, xws li panasonic servo system, nano tswj photoelectric encoder; |

| 3. Circular arc tooth synchronous belt deceleration system muaj qhov zoo ntawm kev ua haujlwm siab, lub neej ntev, tsis tshua muaj suab nrov thiab txij nkawm dawb. Tam sim no, ntau tus neeg siv khoom hauv tsev tseem tab tom txuas ntxiv siv worm worm reducer. Qhov laj thawj tseem ceeb yog tias lawv cov servo system tseem siv cov analog ceev tswj hom. Vim lub zero drift thiab imbalance ntawm lub analog tswj, nws yuav ua tsis tau kiag li xoom ceev, yog li nws yog tsim nyog los siv tus kheej-locking nyhuv ntawm tus cab cab kom nres. Thiab peb siv cov ntshiab digital theem-lock voj txoj hauj lwm mem tes tswj hom, tsis muaj xoom drift, tsis muaj qhov tsis sib xws; |

| 4. Txais cov khoom siv siab-precision pob thiab xaim pas nrig loading, ruaj khov, lub neej ntev ntawm lub tshuab kuaj, zoo ruaj khov thiab txuag hluav taws xob; |

| 5. Kev tiv thaiv ntau yam. Xws li: lub zog txuas ntawm ntau yam kev tiv thaiv hluav taws xob, software ib feem ntawm overload, tiv thaiv overshift, mechanical forced kev ruaj ntseg txwv kev tiv thaiv; |

| 6. Yooj yim, txhim khu kev qha, thiab muaj zog cov neeg siv kev lag luam interface. |

| Cov qauv |

| GB 13022, GB 8808, GB 1040, GB 4850, GB 7753, GB 7754, GB 453, GB / T 17200, GB / T 16578,GB/T 7122,GB/T 2790,GB/T 2791,GB/T 2792,GB/T 17590,ISO 37,JIS P8113,QB / T 2358, QB / T 1130, ASTM D5748, ASTM D638, ASTM D882, GB / T13203-2007 cov qauv. |